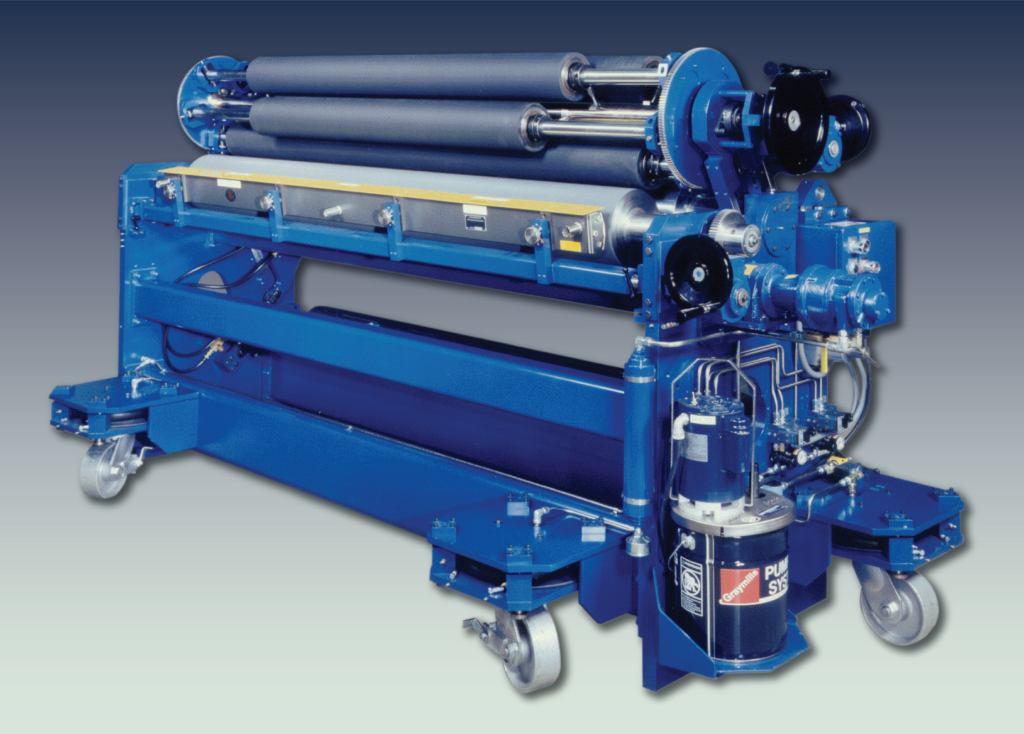

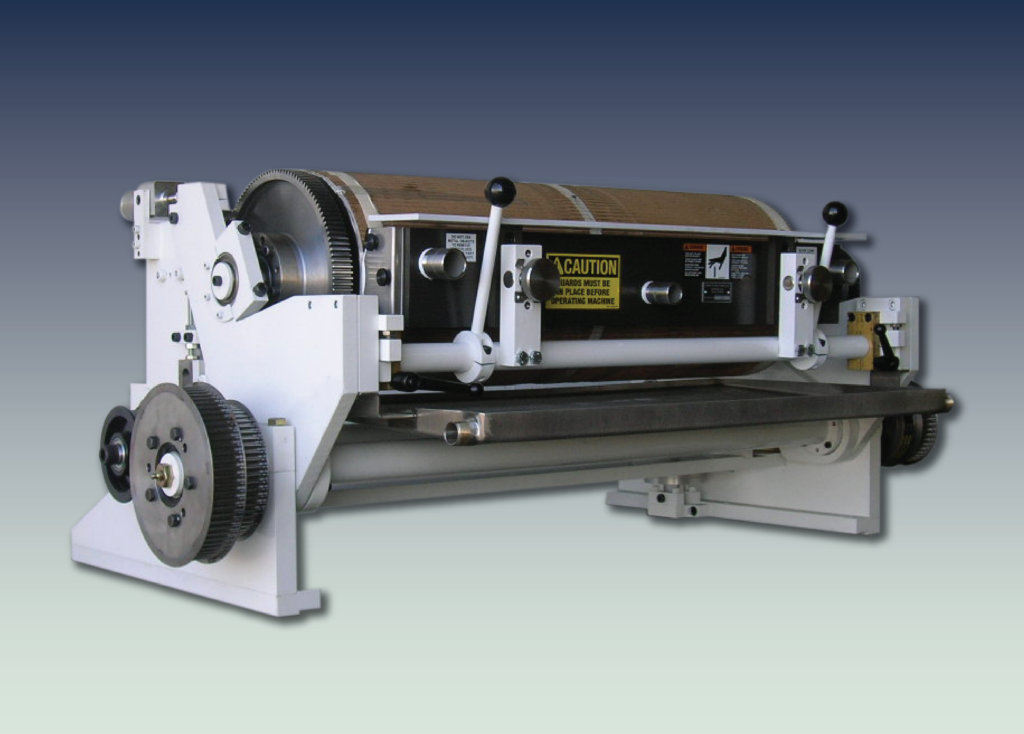

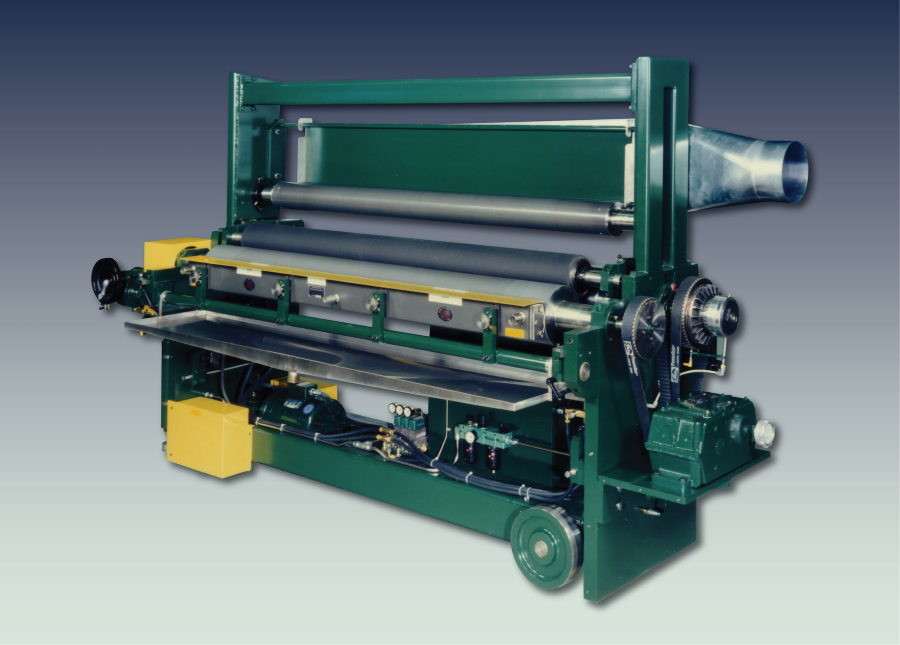

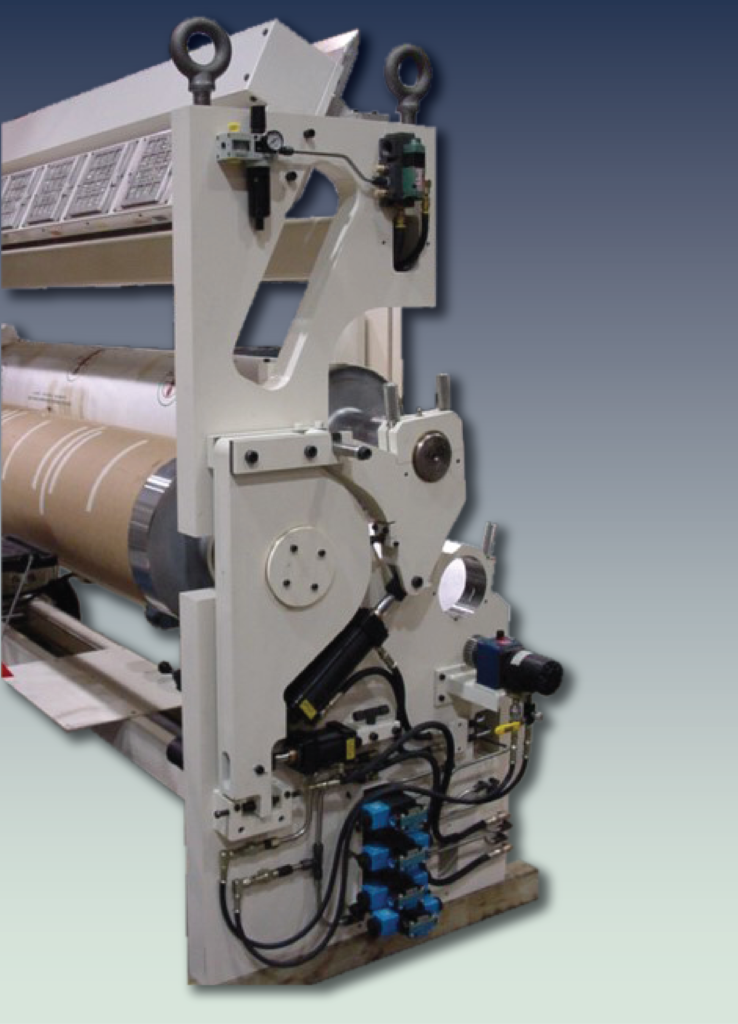

Gravure Coaters

Gravure coating is a proven tinting and coating transfer method utilizing one rubber covered roll and one steel or ceramic covered roll. Coatings are applied and metered to the engraved roll via a pan and single blade system or an enclosed doctor blade system. As the engraved roll rotates, the fluid is delivered to the engraved cells, metered and then transferred to the substrate at the nip point of the rubber and engraved roll.

Many factors such as cell volume, rubber durometer and thickness, viscosity, metering options and speed determine your success. In general, the gravure coating process is the most cost-effective method for fluid transfer. When coatings are required to meet certain registration and lay down criteria not attainable by this method, Printco will utilize its Flexographic coating format.

You can rely on Printco to evaluate and assess your specific process needs. Our designs range from standard manual adjustment to full automation. Please contact a Printco representative to determine the best fit for you.

Common coatings include: Varnish, Wax, Lotion and Tinting.